Innovative spare parts designed for

Precision, Durability.

Metals industry with by high technology innovation

The Highest Quality

Quality Assurance with advanced technology

Empowering your drive with top-quality, durable, and reliable spare parts.

- Six Sigma and Lean Manufacturing: Implementation of these methodologies minimizes defects and ensures adherence to stringent quality standards.

- Non-Destructive Testing (NDT): Advanced testing methods detect internal defects without damaging parts.

- Traceability Systems: Use of QR codes or RFID tags ensures every part can be traced back to its manufacturing origin, ensuring accountability and reliability.

WHAT WE DO

A Selection Of Industries We Serve

Precision-engineered parts ensuring reliability, safety, and long-lasting performance

SPECIAL SERVICES

Healthcare Industries

Precision-engineered healthcare parts ensuring reliability, safety, innovation, and patient care.

Custom Metal Part For Your Next Project

HOW WE WORK

Top Working Process

Building trust, ensuring reliability with durable and precise parts.

Material Selection

As per requirement checking hardness, strength, wear resistance, and machinability of the material.

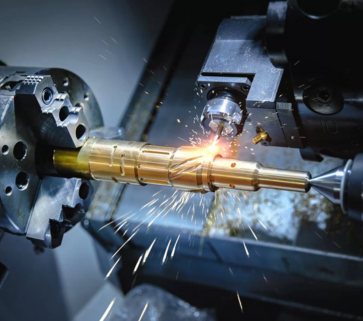

Cutting and Shaping

This process involves using Computer Numerical Control (CNC) machines to precisely cut, shape, and form the material.

Finishing and Quality Control

After the initial shaping, parts often require finishing processes to improve surface quality, achieve tight tolerances.

Packaging and Delivery

After machining and quality control, parts are carefully packaged to ensure safe transport to customers or assembly lines.

TESTIMONIALS

Hear From Some Previous Clients

Where technology, craftsmanship, and trust meet for superior parts.

From our experience working with customers who use the Citizen Sliding Head Model A20, it’s evident that this machine delivers exceptional value. Its multi-axis machining and automatic tool changing have proven to be highly effective in reducing setup times and increasing overall production efficiency. We’ve seen many clients expand their production capacity and significantly enhance part quality thanks to the precision of the A20.

Working with manufacturers who use the Citizen A20, we’ve observed an impressive improvement in the quality of the parts being produced. The machine’s accuracy and tight tolerances allow for better consistency, which aligns with the high standards required by industries like automotive and aerospace. As a supplier of quality control instruments, we’ve seen fewer issues with defective parts, leading to improved production outcomes for our customers.

Our customers who rely on the Citizen Sliding Head Model A20 for machining small, complex parts have shared great feedback on the machine’s efficiency and reliability. The precise cutting capabilities of the A20 minimize wear and tear on tools and reduce coolant consumption, which improves the overall machining process. It’s a highly effective machine that allows our customers to maintain optimal productivity while using less cutting fluid.

Citizen Sliding Head

Process & Advantages

High Precision and Accuracy, Versatility and Flexibility, High-Speed Machining.

The Citizen Sliding Head Model A20 is a high-performance CNC lathe designed for precision machining of complex parts, often used in the automotive, medical, and aerospace industries. Its unique sliding headstock design offers several advantages, particularly in the production of small, intricate, and high-precision components.

Contact Us

Address

- Office/Sales

- Sr No 27/1-2+2

- Kharadi

- Pune- 411014

- Factory

- Gat No 879/1

- Sanaswadi Nagar Road

- Pune- 412216