About Us

Elite Engineerings

Company Overview

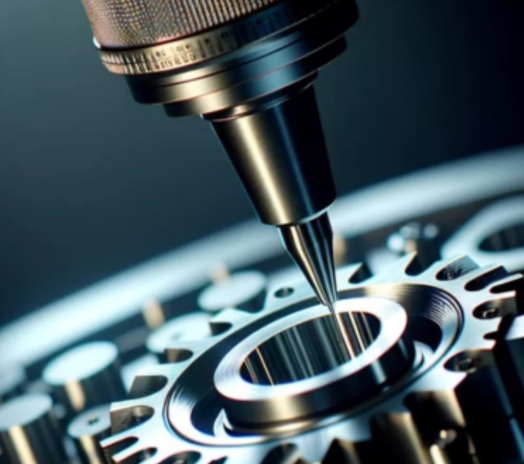

Your trusted partner for high-quality, durable, and precision-engineered spare parts.

Founded in 2021, our manufacturing unit has rapidly emerged as a reliable and innovative provider of high-quality precision components. With a commitment to excellence, we specialize in delivering superior spare parts crafted to meet the diverse needs of industries such as automotive, healthcare, and engineering.

OUR VALUES

Our Mission

Trusted by industries for precision-crafted parts that last longer.

Our mission is to deliver high-quality, precision-engineered components that drive innovation and reliability across industries. We are committed to excellence in manufacturing, leveraging advanced technologies like CNC and sliding head machines to produce components with exceptional accuracy and durability.

With a focus on precision, integrity, and customer satisfaction, our goal is to be a trusted leader in the manufacturing sector, contributing to the growth and success of our clients worldwide.

WHAT WE DO

A Selection Of Industries We Serve

Pioneering parts solutions that prioritize quality, durability, and innovation.

2021

We began our journey by serving the automobile sector, providing high-precision components tailored to meet the rigorous demands of the industry.

2022

we expanded into the healthcare industry in 2022, providing critical components for medical equipment that require the highest standards of quality and reliability.

2023

By 2023, we further broadened our scope by entering the electric industry, providing innovative and durable components tailored to its evolving needs.

2023

we diversified further into the optical fiber sector, supporting internet infrastructure with precision-engineered components essential for connectivity.

2024

we expanded into the plastic molding segment, delivering high-performance plastic components for various applications like automobile, healthcare.

Innovation and Sustainability

Advanced Manufacturing Techniques, Eco-friendly Materials and Processes

Driving sustainability through innovative solutions for a cleaner, efficient future.

We utilize CNC machines and sliding head lathes that are capable of performing intricate, high-precision tasks. These technologies allow us to manufacture complex parts with minimal waste, higher accuracy, and shorter lead times, ensuring optimal efficiency and quality.

We work closely with our clients to develop customized solutions, from designing new components to refining existing products. Whether it’s improving the durability of medical parts or enhancing the performance of automotive components, innovation is embedded in every project we undertake.

We prioritize the use of sustainable materials, such as recyclable plastics and eco-friendly coatings like Teflon, that minimize environmental impact. We also continuously seek to adopt processes that reduce material waste, energy consumption, and emissions during manufacturing.